The energy mapping is the basis for further work in the planning phase. Next come three activities:

- Creating a baseline on the basis of data collected from the energy mapping.

- Identifying representative and measurable energy indicators (KPIs). These should follow a KPI structure.

- Defining energy objectives and targets, and implement in the organisation.

![]() What should be done

What should be done

Baseline

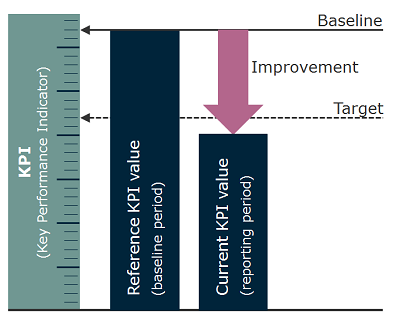

Based on the energy mapping, the organization should establish a baseline, or several, for representative periods of energy consumption. Then, the change in energy performance should be measured against the baseline.

The purpose of a baseline is, for example, to measure improvement over time, and assess whether the energy management system helps the organisation achieve its goals and have a good use of energy (avoiding energy waste). An organization should therefore periodically evaluate their performance against the baseline and possibly improve the trend through (deviation management / corrective measures) if the energy consumption is higher than anticipated.

The baseline may be for example the actual energy use for a year of normal production, but should be adjusted if there are significant changes to the installation.

It is recommended to have a method description for when and how the baseline should be adjusted, for example if the following conditions are met:

- Changes in working patterns, energy systems and processes (e.g. a new gas turbine).

- KPIs are no longer representative of the organisation's energy use (e.g. conversion from gas turbines to partial electrification).

KPIs

KPI (‘‘Key Performance Indicator’’) is the term used in the oil and gas industry to describe energy indicators. The term KPI is therefore used in this guide. The ISO 50001 standard for energy management uses the term ENPI (“Energy Performance Indicator”), defined as a quantitative value or target for energy performance as defined by the organisation. The term KPI used in this section is the same as ENPI from the standard.

To establish good and quantifiable KPIs, it is usually necessary to analyse what affects the relevant KPI. A good start would be to make some simplistic measurements or calculations to set a preliminary KPI. Then it may be necessary to carry-out a more detailed analysis at a component or system level to find a more optimal value for KPI to be used.

| Exemple of KPIs: |

|---|

|

Experience from the industry project shows that defining good KPIs can be time consuming and requires the involvement of people with expertise in different areas. By definingKPIs through such a process ensures that they align with the rest of the system with due consideration paid to their value, content, context and possible influence from other systems.

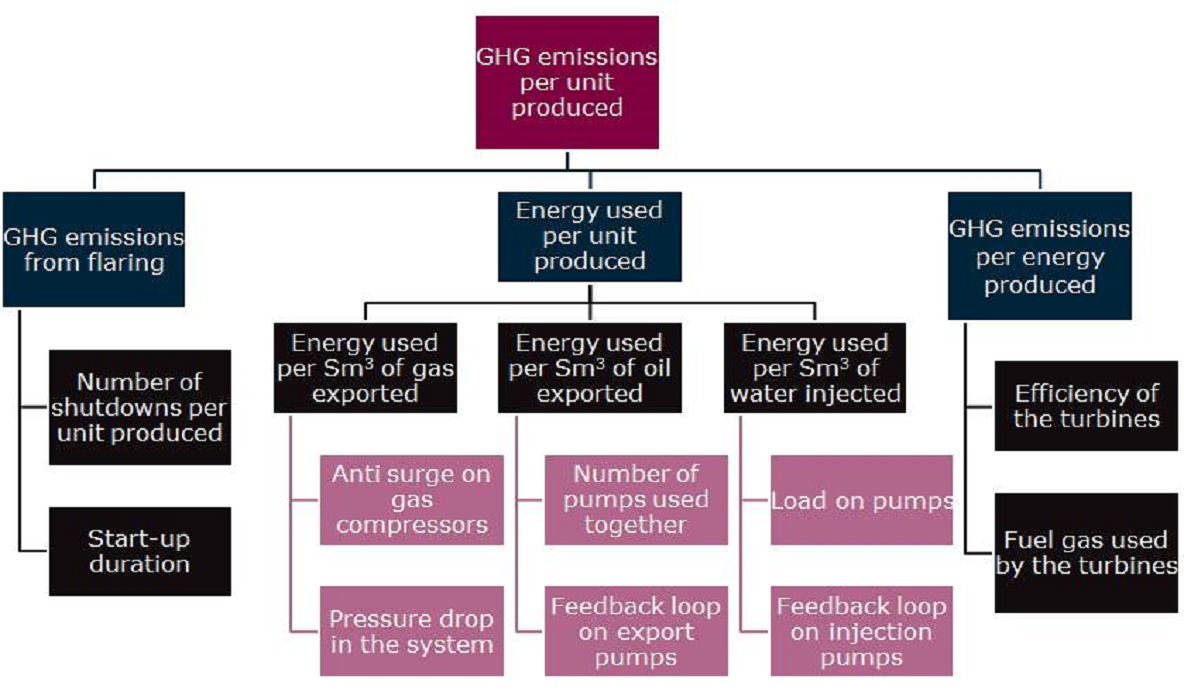

Since different people in the organisation can influence different factors, you may want to organize the KPIs in a structured hierarchy. This structure should start with an overall KPI which is valid for the entire installation and then split-up in other KPIs that are more specific to a particular department / unit or workspace.

| Exemples of KPIs for the energy management system, related to ideas |

|---|

|

KPIs at the bottom of the hierarchy should be parameters that operators and other personnel with specific competence can influence directly through their daily work.

A schematic example of a KPI structure is shown below.

Energy objectives and targets

Towards the end of the planning phase, the organisation should:

- Define energy objectives and associated targets.

- Establish an action plan for energy management.

When this is done, the organisation can move forward to the implementation of energy management.

The targets should be defined according to SMART, which is:

- Specific, this can for example be energy use per unit produced, to account for variations in the activity level.

- Measurable, it should be possible to document them.

- Achievable, the targets can be ambitious but should always remain achievable.

- Relevant, the targets should be possible to meet by implementing improvement measures.

- Time-bound, the targets need to be met within a given timeframe.

It is important that the objectives and associated targets are consistent with the defined energy policy. The targets should be set with the help and input from employees throughout the organisation, and the initiative should come from the top management. It is important to include employees at multiple levels in the organisation to ensure a joint ownership of the targets. The targets must be set in accordance with the KPIs as defined previously.

| Konkraft, Klimakur and targets for the industry |

|---|

|

Konkraft is a collaboration arena for the Norwegian oil and gas association (Norsk olje og gass), Norwegian Industries (Norsk Industri), the Norwegian Shipowners' Association (Norges Rederiforbund) and the Norwegian Confederation of Trade Unions ( Landsorganisasjonen). Part of the Konfraft mandate is to ensure competitiveness on the Norwegian Contienental Shelf (NCS) and attractiveness for development and uptake new technologies. Konkraft published a report in 2009 on the petroleum industry and climate issues where they identified that a reduction potential of 800 000 tonnes of CO2 could be achieved by 2013. The Klimakur 2020 work identified a further reduction potential of 200 000 tonnes of CO2, totalling a reduction potential of 1 million tonnes of CO2 by 2020. Statoil stated that the company will take responsibility for 80% of the identified reduction potential, as it accounts for about 80% of production on the NCS. |

One way to ensure that targets are visible is by addressing them as a topic during morning meetings. The targets should be an integral part of existing systems and processes.

The targets may be based on external drivers (such as the Konkraft target on CO2 reductions). It is important to remember setting targets which employees can influence.

In addition to the targets, an action plan must be implemented and maintained so that the organisation can achieve its objectives.

The action plan should contain:

- Improvement measures and activities to reach the targets and associated deadlines.

- Who is responsible for implementing the improvement measures.

- How to quantify the improvements from the measures and quantify targets to see if the energy efficiency really improved.

![]() Who should be involved

Who should be involved

Employees involved for defining the energy objectives and targets should be many of the same who were involved in energy mapping, see list below. To ensure management support, more people from higher up in the organisation should also be involved in the process. Finally, it is also important to involve the units that will contribute to reaching the targets.

Employees with a good knowledge of existing management systems should be included.

Persons to involve when establishing a baseline, energy indicators (KPIs) and targets include:

- Energy Manager

- Director of Operations

- Operations manager

- HSE manager

- Offshore team leader operations (OTLD - offshore team leader drift)

- Offshore Installation Manager (OIM)

- Responsible for rotating machinery

- Process engineer

- Electrical engineer

- Personnel from drilling

- Other operational personnel

- Project department

![]() What should be documented

What should be documented

For the baseline, energy indicators (KPIs) and targets, the following should be documented:

- Defined baseline(s), must also be maintained and recorded.

- Methods for establishing and updating KPIs should be recorded and reviewed regularly.

- Energy objectives and targets in accordance with legal requirements and other requirements.

- Action Plan for energy efficiency.

![]() Challenges and opportunities

Challenges and opportunities

The experience from the industry project indicates that there are several challenges and potential solutions when establishing baseline, defining energy indicators and targets.

When defining the baseline it is often a challenge to find which year can be classified as a normal production year

Production varies from year to year, and in addition deviations from the norm often occur. After a baseline is chosen, it is important to update it if new information is available, or if major changes are implemented on installation that may affect the baseline. The use of a baseline relative to the production level may also make it easier to account for changes in activity.

Improving the KPIs may require a comprehensive analysis

Better understanding the energy consumption from the energy mapping can make it easier to know which parameters / input data are required for such an analysis. The analysis can then make it easier to define relevant KPIs.

Establishing the KPIs is resource-intensive, many people should be involved

Although it is resource-intensive to define KPIs, the organisation as a whole can benefit from this process in the long run. It becomes easier to clarify and follow-up responsibilities, which can make work easier in the future.

It is challenging to find KPIs that satisfy all requirements, and in addition, some of the KPIs counteract each other

KPIs that counteract each other should be avoided and a comprehensive survey should be conducted to understand relationships better.

It is challenging to set objectives and targets that have a good grounding in the organisation, are realistic, yet optimistic and challenging.

It is important to include the right people to establish targets. Therefore, it is recommended that several levels of the organisation are included in the process and in addition, that those persons actually have the necessary authority for defining the targets.

There are not necessarily easy solutions to all challenges identified with KPIs, however, opportunities arise from having a good KPI structure and targets:

- Good KPIs can lead to easier management of the facility and improved energy efficiency.

- Work with KPIs can already start in the design phase and that can influence the way installations are designed and how they perform later.

- It is important to find the right motivation for the employees. This can be done using cost as an illustrative parameter. This can have a positive impact in terms of savings.

![]() Energy management in practice

Energy management in practice

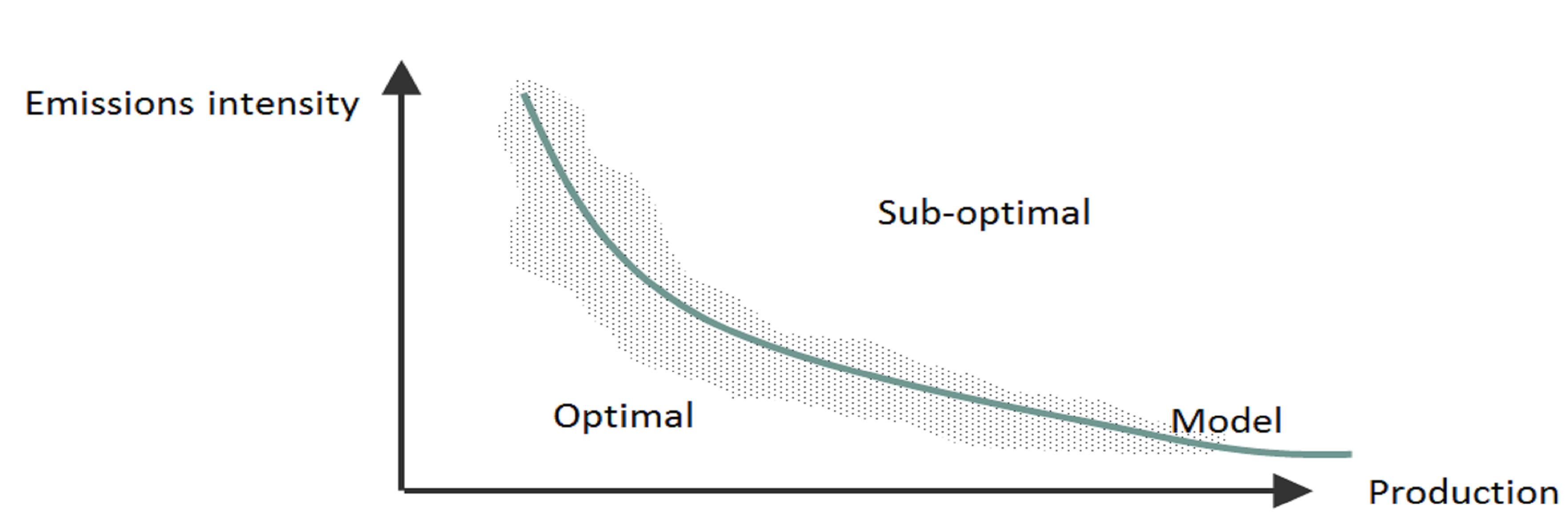

| Regression analysis for the GHG emissions intensity on Oseberg, Statoil |

|---|

|

Statoil analysed the emission intensity on Oseberg, as a function of production. Based on the production data gathered, Statoil did a regression analysis to find the optimal range for production to avoid excessively high emission intensity. In addition, the model can be used to help operators benchmark their operations on a daily basis.

|

![]() Where do you find this in ISO 50001?

Where do you find this in ISO 50001?

- Chapter 4.4.4 Baseline energy use

- Chapter 4.4.5 Energy performance indicators

- Chapter 4.4.6 Energy objectives, targets and energy management action plans