An energy review should be in line with the energy policy of the company and should include activities that continually improve energy performance. It shall include in particular a mapping of the organization's activities which can affect the energy performance.

The energy review is important to:

- Understand the energy use of the organization by creating an overview of energy flows,

- Identify improvement opportunities and focus efforts toward critical areas,

- Ensuring adequate overview and control (for example, registering unexpected changes or results),

- Predict the expected energy use in the next period,

- Measure and evaluate the effect of improvement activities and projects, and

- Report on the energy performance and improve the bottom line through improved energy efficiency.

![]() What should be done

What should be done

The energy review is carried-out through an analysis of available data for the company or installation. It is important to identify all significant energy sources and associated uses. It is also possible to implement this on a detailed equipment level by creating a register that can be used in several contexts (e.g. an electrical load list).

The energy review is part of a process that starts with a mapping, before identifying focus areas to be assessed further and finally the possibilities of various improvement measures, see figure below.

The energy review can be done through workshops with the relevant people for example. In any case, experience among the companies has shown that it is important to have the right people involved in the process, this way the organisation ensures that the right expertise is involved.

Parts of the mapping will be based on data from sensors and other measurements, but it is most likely not sufficient for establishing a complete overview of energy uses.

Information is generally collected based on:

- Operational data,

- Energy analysis,

- In-depth studies for specific processes, and

- A full analysis of an installation.

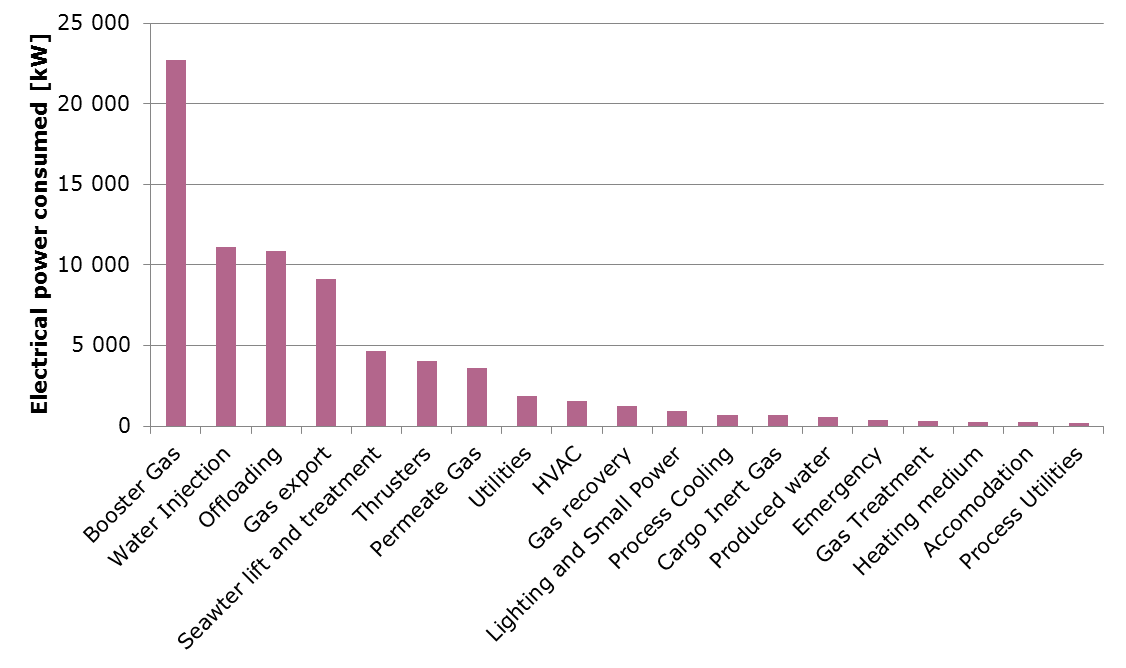

In order to choose the focus area, it is important to understand that typically 80 % of all the energy use/production/costs are related to 20 % of the equipment. It can therefore be smart to choose the focus areas based on their contribution to the energy use. However, don’t forget that the sum of many small changes can make a big impact. Energy management is a group effort where all contributions can lead to improvements.

The experience from the industry project shows that several companies have carried-out an energy mapping but do not have a systematic approach with regard to documentation and follow-up.

Below is an example of how results of an energy mapping may look like. In this example the main electric power users for an FPSO are shown.

![]() Who should be involved

Who should be involved

In order to achieve the best possible energy review, several people from different parts of the organization should be involved. It is very important to include operators in this process, as they have a lot of useful knowledge, and also because they are the ones ultimately doing the job. This will hopefully lead to more support and a better ownership.

An example of relevant participants is given below:

- Energy Manager

- Director of Operations

- Operations manager

- HSE manager

- Offshore team leader operations (OTLD - offshore team leader drift)

- Offshore Installation Manager (OIM)

- Responsible for rotating machinery

- Process engineer

- Electrical engineer

- Personnel from drilling

- Other operational personnel

- Project department

![]() What should be documented

What should be documented

The energy management system should include a written procedure describing the method and process of how an energy review is implemented and maintained.

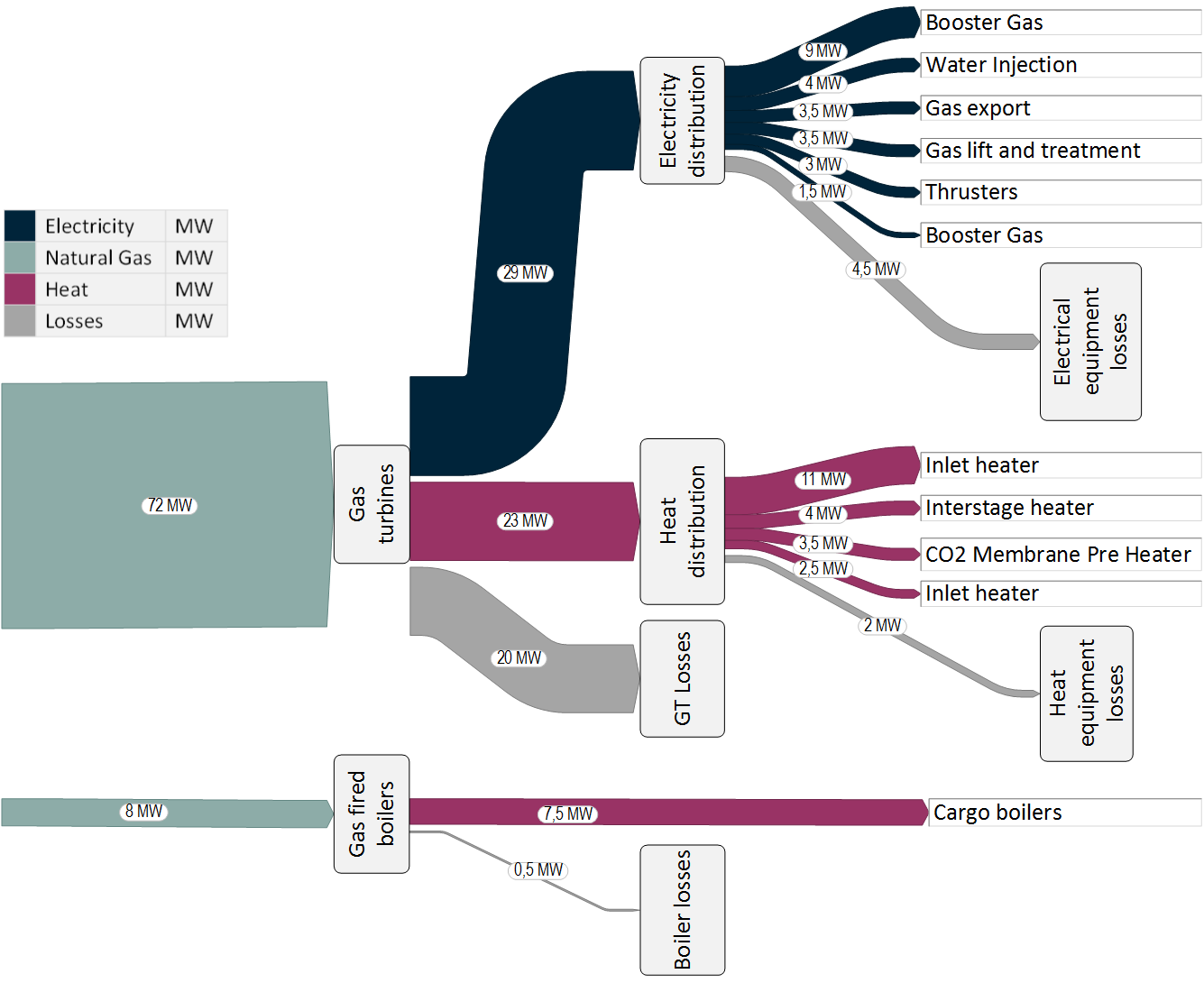

One of the key things to document is where the energy comes from (an energy carrier, for example, natural gas, diesel, etc.) and what it is used for. Experience gathered through the industry project shows that there are different ways to document this in practice. A method that some companies use is to show the energy consumption on a Sankey diagram. An alternative is to use an energy register, for example with a user-friendly table format.

Below is an example of a Sankey diagram for an FPSO, similar diagrams are used by some companies.

![]() Challenges and opportunities

Challenges and opportunities

The experience from the industry indicates that there are various challenges and potential solutions to what may occur during the energy review.

It is difficult to access or find useful information

It is important to use data that already exists, for example in systems like OSIsoft PI, System One, or other systems that store operational data.

Those responsible for implementing the energy review lack knowledge of the installation

It is important to involve experienced personnel with good depth knowledge of the current installation to be reviewed.

The installation is too old and there is not enough data available to make a good energy mapping.

It should be considered to install multiple sensors to get access to the necessary information. Those sensors could be useful later when following-up the results of improvement actions.

The responsible for the external environment is left in charge of the energy review without an adequate mandate

The management should arrange to provide the energy leader a mandate and communicate this throughout the organisation.

![]() Energy management in practice

Energy management in practice

| Energy review at BP |

|---|

|

BP completed a major project for energy review in 2012, covering three fields. This was done during two-days workshops per field. BP made sure to have a good facilitator who was familiar with the methodology and who clearly facilitated the process. Participants from different parts of the organization joined the workshops, such as operational staff, the HSE and operations directors, the responsible for external environment, the Offshore Installation Manager and others. |

| Implementing energy management at the Oseberg field |

|---|

|

In 2014, Statoil received support from Enova for implementing energy management at the Oseberg field. The purpose of the project in cooperation with Enova was to reduce energy consumption by 19.9 GWh annually. The company started by making an overview of how energy is produced and how it is used. Statoil wanted to optimise the use of the gas turbines with the highest possible efficiency. The company considered improvement measures for both the main processes and support processes, as well as flaring. Statoil tries to follow the best practice according to international standards and this will result in a gain for energy efficiency. Implementation of energy management at Oseberg led to:

|

| Energy mapping at Statoil |

|---|

|

Statoil has one energy coordinator per installation, not full-time, but with a dedicated percent of the time to spend on energy management. Part of the time is to be spent on creating an action plan for the installation the person is responsible for. Part of the plan includes an energy mapping with the help of a Sankey diagram, which is later used for identifying improvement opportunities. |

![]() Where do you find this in ISO 50001?

Where do you find this in ISO 50001?

- Chapter 4.4 Energy planning

- Chapter 4.4.3 Energy review