Energy mapping is the basis for further work in the planning phase. After it is completed, there is a requirement to create a baseline based on data collected from the mapping.

A baseline can be static and based on, for example, historical data, but it can also be based on modelling.

In this section, you will find descriptions of the process to establish a baseline, but also the relationship between baseline, energy Key Performance Indicators (KPIs) and objectives.

![]() What should be done

What should be done

There is a requirement to establish a baseline before you establish a KPI structure and objectives. The relationship between these is described in the section below.

General process and definitions

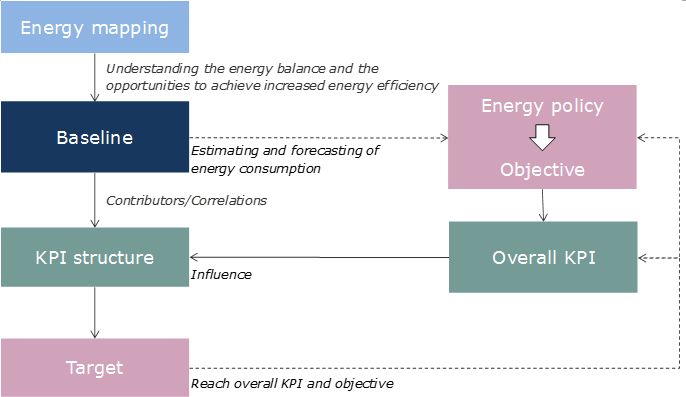

A general process that includes energy mapping, baseline, KPIs and objectives are shown in the figure below.

To establish a baseline, you should understand your own energy consumption through for example an energy mapping. The baseline provides input for both the main objective and KPI structure, through helping to identify contributors and correlations and to make projections for future energy consumption.

A KPI structure can be established with input from the baseline, but also with the influence of an overall KPI (as defined at the company level or field/installation level). When a KPI structure is established, targets can then be established for each of the KPIs to reach the main objective for the higher level KPI.

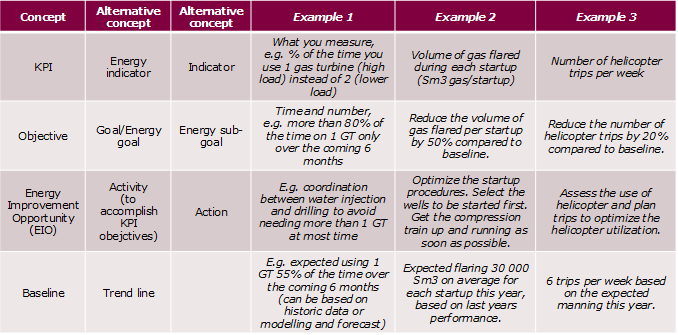

There are many different terms used for baseline, KPIs and objectives. A selection of those used on the website are gathered below in a table with accompanying examples.

Establishing a baseline

The baseline can be described as information used as a basis for comparing other information.

Based on the energy mapping, the organization should establish a baseline, or several, for representative periods of energy consumption. Then, the change in energy performance should be measured against the baseline.

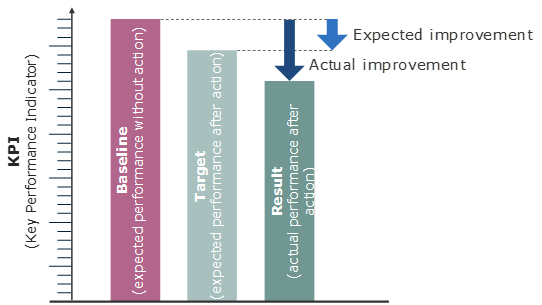

The purpose of a baseline is, for example, to measure improvement over time, and assess whether the energy management system helps the organisation achieve its goals and have a good use of energy (avoiding energy waste). An organization should therefore periodically evaluate their performance against the baseline and possibly improve the trend through (deviation management / corrective measures) if the energy consumption is higher than expected.

The baseline may be for example the actual energy use for a year of normal production, but should be adjusted if there are significant changes to the installation.

It is recommended to have a method description for when and how the baseline should be adjusted, for example if the following conditions are met:

- Changes in working patterns, energy systems and processes (e.g. a new gas turbine).

![]() Who should be involved

Who should be involved

Employees involved for defining the baseline should be many of the same who were involved in energy mapping, see list below. To ensure management support, more people from higher up in the organisation should also be involved in the process. Finally, it is also important to involve the units that will contribute to reaching the objectives.

Employees with a good knowledge of existing management systems should be included.

People to involve in this phase of the planning could include:

- Energy Manager

- Director of Operations

- Operations manager

- HSE manager

- Offshore team leader operations (OTLD - Offshore Team Leader Drift)

- Offshore Installation Manager (OIM)

- Responsible for rotating machinery

- Process engineer

- Electrical engineer

- Personnel from drilling

- Other operational personnel

- Project department

![]() What should be documented

What should be documented

For the baseline, the following should be documented:

- Established and defined baseline(s), one or several, must be documented, but also maintained and changed if necessary. It is important to note that one must be careful not to change the baseline, as this can create challenges - see below.

- Action Plan for Energy Efficiency.

![]() Challenges and opportunities

Challenges and opportunities

A challenge when defining the baseline is to find which year that can be classified as a 'normal' year of production. There are regularly deviations from the norm, and this can be difficult to consider when the baseline is defined.

After a baseline is chosen, it is important to update it if new information comes to light, or major changes are to be implemented on an installation that may affect the baseline. There may also be a possibility to create a baseline which is related to production as this will be more independent of individual factors.

It is difficult to create baselines for mature fields and fields in the tail production.

This can be solved by breaking up the production process into several parts and establish baselines for several of the sub-processes. In this way, the baselines will not be as vulnerable and affected by the field's complexity. This also applies to larger, more complex fields with many ''tie-ins''.

![]() Where do you find this in ISO 50001?

Where do you find this in ISO 50001?

- Chapter 4.4.4 Baseline energy use