Procurement of energy services, products, equipment and energy (including raw materials) can affect the energy efficiency of the installation/field and the energy performance of the company. Energy management in procurement is first and foremost about considering energy efficiency as a purchasing criterion, as well as having good evaluation methods through the purchasing process.

Energy management in the procurement process includes both purchase of equipment and products, but also purchase of services and e.g. logistics.

It is expected that future updates of e.g. ISO standards (ISO 14 001, 50 001) will contribute to increased focus on the life-cycle perspective and that the management systems will include larger parts of the supply chain.

![]() What should be done?

What should be done?

The following topics should be considered and/or implemented as a part of the procurement process:

- Establish good communication between the ordering unit and purchasing department early in the process so that the criteria for the order are a result of the cooperation between these departments. Set energy efficiency as one of the criteria for purchase evaluation. Ideally, the approach should be presented as a life-cycle analysis, so that the entire process from design to disposal, in addition to operation and maintenance, is considered.

- Communicate the list of criteria to your supplier, and make it clear that energy efficiency will be an evaluation parameter in the procurement process.

- In the decision-making process, there should be a dialogue between the ordering unit and the purchasing department to ensure that issues related to energy efficiency are adequately considered. It is important to be able to describe energy consumption in monetary terms to highlight the economic benefits – seen in a life-cycle perspective.

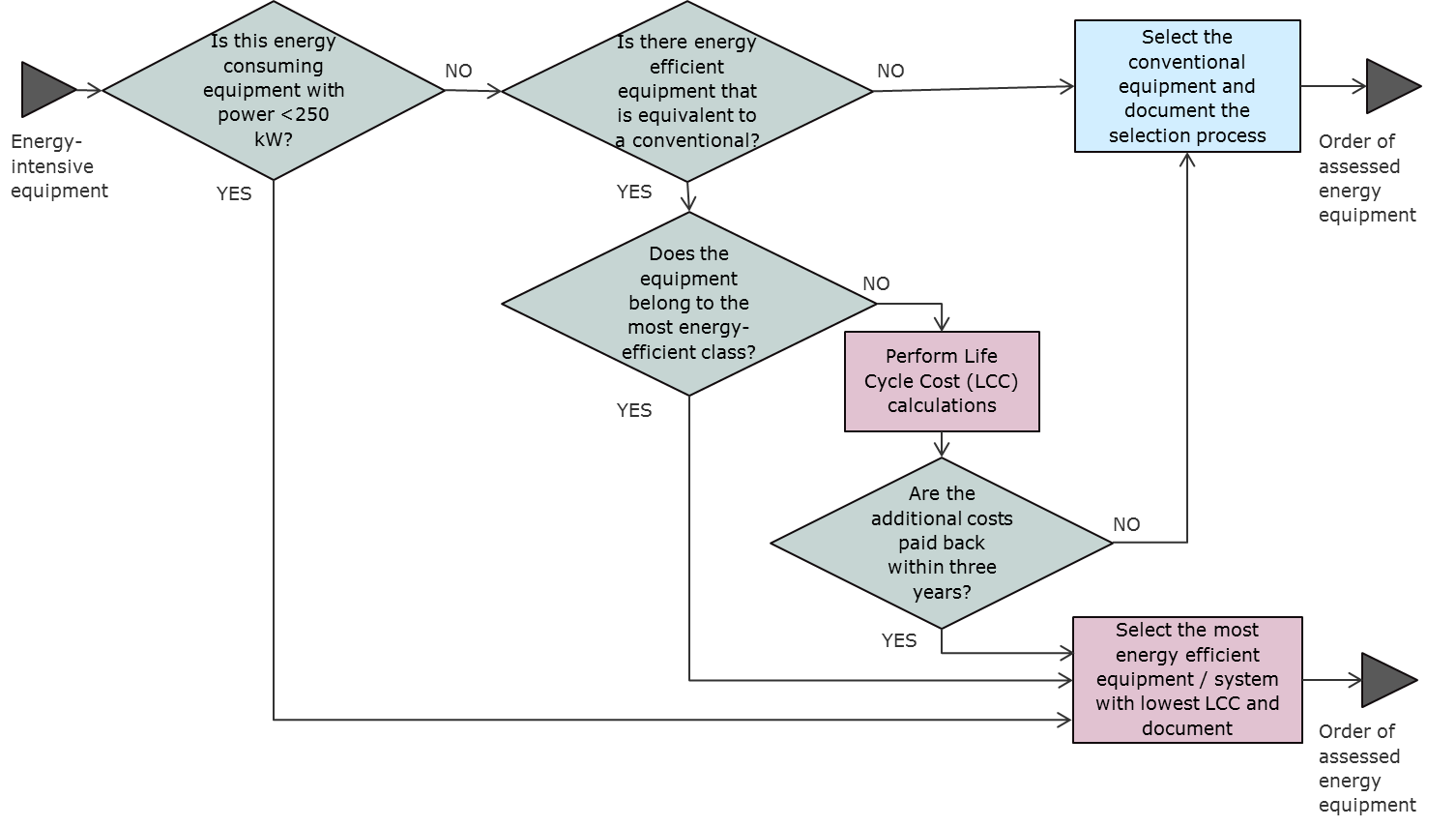

During procurement of equipment or products, a flowchart can be used to assist with the evaluation of what equipment provides the highest energy performance (most energy efficient). This chart should be shared with the purchasing department. Below is an example of a simple process description.

Energy efficient equipment can be more expensive to purchase compared to alternatives. It is therefore important to highlight the benefits (e.g. in the form of reduced operating costs, reduced emissions, increased sales of gas, etc.) so that this increased cost can be justified. A life-cycle analysis of anticipated costs and savings compared to conventional equipment will also support the decision basis. There are established arrangements for public funding with reference to choice of suppliers as well as for the purchase of equipment.

Although existing practice sets supplier requirements in the procurement process, it is possible to emphasise energy performance in addition to traditional evaluation criteria and thus achieve greater overall energy efficiency.

Energy management in logistics (rigs and ships)

To a large extent, oil companies receive the fuel bill from contracting of ships and rigs. This results in diminished incentives for ship owners' work towards and investment in improved energy efficiency. In addition, most oil companies set few requirements regarding energy efficiency and emissions towards ship owners.

Energy efficiency, along with the choice of alternative fuels, represents the two most important measures to realize maximum CO2 reductions from rigs and vessels. There is a great potential, but care must be taken to ensure that this potential is actually reached. In this context oil companies can play a greater role in the future in dialogue with its suppliers, possibly facilitated by a third party facilitator.

Regulatory requirements, barriers and opportunities must be considered alongside one other to achieve good overall results. This section reviews these three areas at a high level. It is a complex and extensive subject, and more detailed information is included as an attachment:

The current legislation imposes certain constraints via the Energy Efficiency Design Index and the Ship Energy Efficiency Management Plan, but they do not apply to all types of vessels nor are they particularly ambitious. Meanwhile, there are currently on-going regulatory processes that suggest stricter requirements in the future.

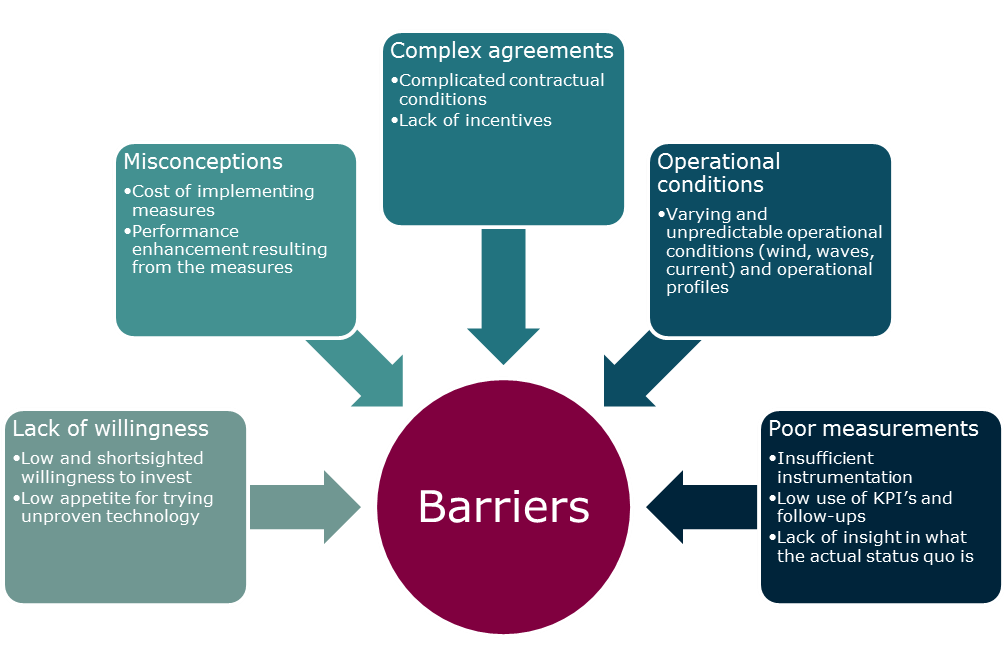

Regulatory requirements in themselves are necessary but not sufficient to achieve energy efficient operation. In addition, there are some key barriers in the way. These are summarized in the figure below.

Given the barriers as mentioned above, there still exists a large range of possibilities. It is expensive and risky to choose poor solutions, and offshore vessels and rigs on the Norwegian Continental Shelf may require a greater degree of customization than in other waters. Thus, there is great potential for both industrial cooperation and competition here.

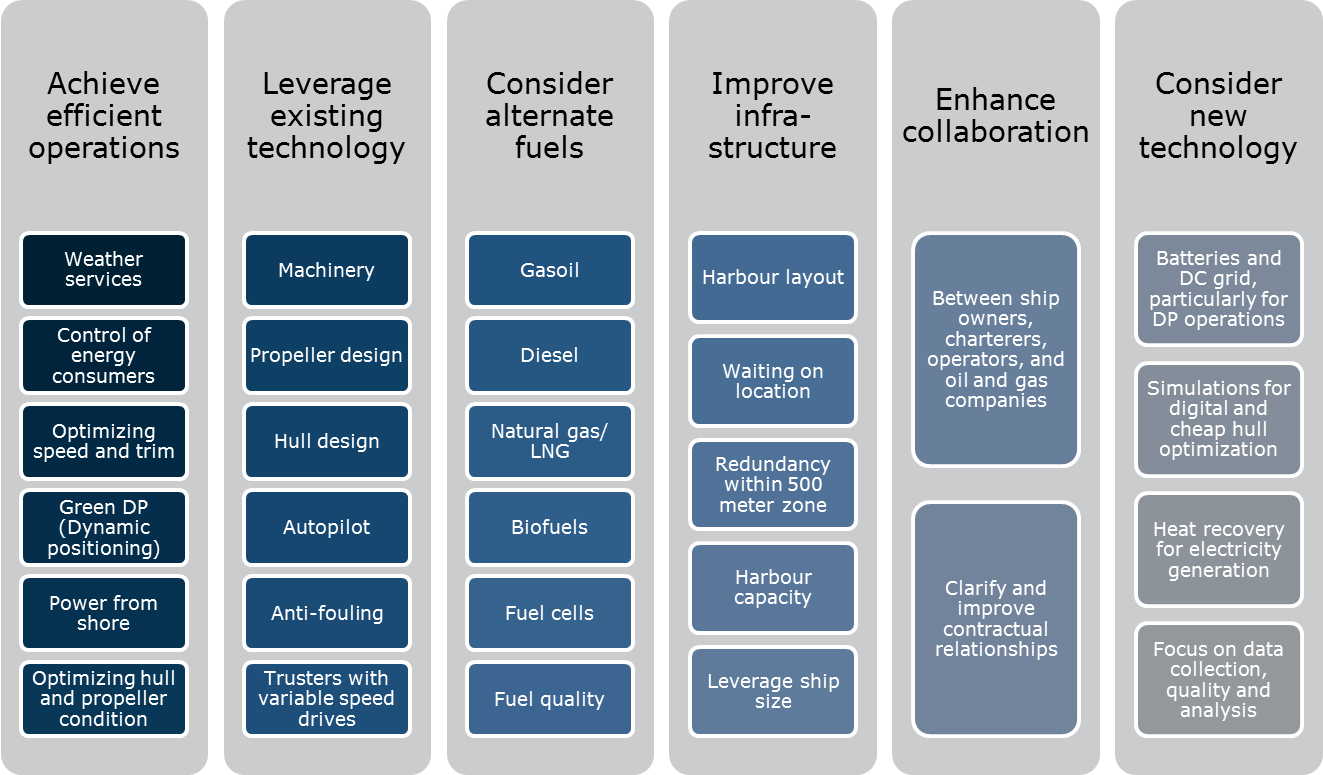

To achieve optimum energy efficiency all stakeholders (i.e. the owner, charterer and management company) must jointly evaluate operation of the fleet using a holistic approach.

Several measures are appropriate and some key areas are summarized in the figure below.

The buying power of oil companies would increase if they joined forces, and some gains might be had through jointly establishing requests for energy efficiency towards their own suppliers. This is further described in the box below.

| Increased cooperation between oil companies - what additional requirements could/should apply to vendors for increased focus on energy efficiency? |

|---|

|

A great potential for increasing energy efficiency of maritime contractors is achievable through increased cooperation between operators. The industry as a whole can for example cooperate to place additional demands on energy and increased energy efficiency in the procurement process and cooperate with marine contractors.

Another great potential exists through finding win-win solutions between the operator and the contractor where the achieved cost savings are split. This is further explained in the success story below. |

![]() Who should be involved?

Who should be involved?

As a principle, the purchasing department for operations and project team should work more closely with the energy team. Further anchoring means that those with financial responsibility for operations and projects are also involved. These are the ones who can contribute to ensuring that energy-efficient solutions are given sufficient priority in purchasing procedures.

Consider the involvement of the following roles and groups:

- Purchasing department

- Engineers who specify/set requirements (ordering unit)

- Logistics department

- Responsible for planning various operations such as drilling activities

- Roles with financial responsibility for operations and projects

- Energy team for operations and projects

- The management (strategic planning and KPIs)

![]() What should be documented?

What should be documented?

Criteria to evaluate energy parameters (e.g. usage, consumption, efficiency) when procuring products, equipment, services that are expected to have a significant impact on the organization's energy performance.

![]() Challenges and opportunities

Challenges and opportunities

What stands in the way of making demands on energy / energy-efficient operation of the supply chain?

To require energy efficient operation poses challenges. Through discussions between involved parties, it may be easier to overcome barriers. These challenges include:

- Often relatively short duration of contracts and thus limited possibilities for setting requirements which for example would include investments (e.g. there is a difference between the operator who will introduce a measure for lower fuel consumption and rig owner who must invest and implement the measure without any direct gains).

- Requirements on performance are sometimes difficult to prove or verify and it is then important to have trust between suppliers and operators.

- Available infrastructure, e.g. access to LNG.

- Forming and developing contracts which allow for changing requirements for increased energy efficiency.

Operators should cooperate more among themselves and set common requirements to suppliers for increased energy efficiency, as well as exploit common resources when fields lie close to each other (e.g. through coordinated transport planning).

In general, increased cooperation and joint effort between operators and suppliers can result in savings and benefits for both parties.

How can I identify performance changes with my suppliers?

Mapping of changes in performance in energy management at the suppliers can be provided through:

- Benchmarking.

- Establishing points of reference such as energy used /unit (for a PSV this could be e.g. ton diesel/day).

- Long-term measurements.

- Establish KPIs jointly with suppliers:

- Drilling rigs: e.g. liter MDC/nm, liter MDC/meter drilled.

- Supply vessels at various stages: e.g. KPIs for transport to/from the field, waiting time, anchor operations.

- Establish a reward system/profit sharing for energy reducing measures together with the suppliers.

- Regular follow-up meetings with vendors where energy management is a fixed point on the agenda

How do I get suppliers to work more closely with us?

Use a two-part checklist, one part for the purchasing department (and the ordering unit) and the other part for the supplier, focusing on energy efficiency. This simultaneously transmits a clear message to suppliers that energy efficiency will be taken into account when evaluating offers.

The purchasing department has no authority to purchase the most energy efficient equipment, and costs are the main criterion.

Energy efficiency is one of many parameters considered in procurement, and often the most energy efficient equipment is put aside due to limitations in space, weight, cost and / or complexity. In the project phase, the evaluation of alternatives should be made as part of BAT evaluations (BAT = Best Available Techniques), but this principle is rarely used in the production phase.

The energy team can contribute to demonstrate the cost savings of choosing energy efficient equipment based on a life cycle analysis, and thus have a greater impact.

Cost savings may include:

- Reduced CO2 emissions (saving CO2 fee and emission quotas)

- Reduced NOX emissions

- Increased sales of gas

The selection of more energy-efficient equipment can also lead to reduced maintenance costs.

When a component is damaged in operation, it is often replaced with an identical one.

This is often the easiest solution when no new risk assessment is needed. For components which have a significant impact on energy consumption, there should be a thorough assessment of these for when they are to be replaced (including both risk assessment and with regards to energy efficiency). Make this an integrated part of procurement procedures.

![]() Energy management in practice

Energy management in practice

|

Joint Industry Project – Energy Efficient Offshore Partners A collaborative project between seven shipping companies within the Norwegian maritime offshore industry as well as two oil companies were facilitated by DNV GL in 2011 and completed in 2014. It is an example of what an industry can achieve together through a collaborative platform. The project intended to create a platform where ship owners could collect and focus their efforts to achieve both increased market penetration, as well as more effectively achieve results in energy efficiency. The value of placing the owner and charterer at the same table were thought to be quite essential, and a key enabler for actually carrying out the project. The project concluded with a theoretical fuel reduction potential of 15.2%, as the average for the seven shipowners overall fuel consumption - equivalent to approximately 500 million NOK. Furthermore, consensus was reached on a framework for communication between owner and charterer to ensure the viability of measures that went across the two parties. In addition, a separate incentive model was created to share the investment and profit level as equally as possible between owner and charterer. After project completion a 6 month pilot implementation of measures and reporting was carried out, and the result was fuel reductions of up to 19%. |

You may find more information about this project here:

- DNV GL: Joint Industry Project Summary – Energy Efficient Offshore Partners, with accompanying article in Tradewinds.

![]() Where do you find this in ISO 50001?

Where do you find this in ISO 50001?

- Chapter 4.5.7 – Procurement of energy services, products equipment and energy